As the RCSI School of Dentistry prepared to welcome its inaugural cohort of Bachelor of Dental Surgery (BDS) students, its team worked on transforming how essential skills are taught and developed.

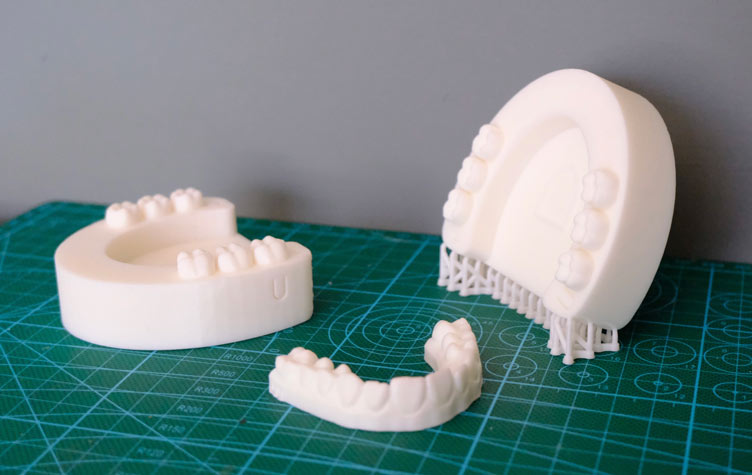

Harnessing advanced 3D printing technology, the School is producing bespoke, in-house dental models to facilitate immersive, hands-on learning. This cutting-edge approach fosters both confidence and competence in a realistic, controlled setting, laying a solid foundation for future clinical practice.

Students will begin their journey at the new Dental Education Centre in Sandyford, Dublin. This purpose-built, state-of-the-art facility has been designed to deliver the highest standard of clinical education. It has 55 clinical simulation units, a fully equipped dental clinic, and custom-designed teaching and learning environments. Within this centre, students will engage in structured skills training alongside interactions with real patients.

Simulation sessions will offer students an immersive introduction to safe and structured clinical training. They will develop a comprehensive range of techniques, including root canal therapy, tooth extractions, restorations, and the administration of local anaesthesia. Emphasis is placed not only on technical mastery but also on cultivating the precision and confidence necessary for effective patient care.

Mirroring real-life procedures

From the outset, students will train using custom 3D-printed teeth, developed in-house using digital scans, high-performance resin materials and advanced additive manufacturing processes. These models support realistic, hands-on learning from the earliest stages of dental education.

This initiative is led by a multidisciplinary team including Dr Niamh Coffey, Senior Lecturer; Ms Mary Joy Soliman, Senior Dental Nurse; Ms Galina Meshcherskaya, Project Implementation Executive; and members of the RCSI Simulation team. Collaborative insights from dental education experts at the University of Plymouth have further enhanced this work.

The 3D-printed models represent a significant advancement in dental training. Unlike conventional plastic teeth, which often lack anatomical variability, these custom models can simulate a wide array of clinical scenarios. This includes decayed, fractured, or otherwise compromised teeth, allowing students to experience diverse and realistic conditions early in their training.

The models’ tactile properties, including texture, resistance, and thickness, are carefully calibrated to replicate the anatomy of enamel, dentine, and pulp. As a result, students receive tactile feedback that closely mirrors real-life procedures.

Bridging the gap

This technological innovation is part of a broader strategy to build clinical capability within a supportive and controlled environment. It enables repeated practice, immediate feedback, and progressive refinement of techniques under expert guidance.

Students are encouraged to learn through trial and error, an essential part of developing a strong foundation in operative dentistry.

This initiative reflects RCSI’s commitment to innovation, excellence, and student-centred learning. These 3D-printed models are more than technical tools. They will help bridge the gap between theoretical instruction and practical application and will help our students evolve into competent, confident, and compassionate dental professionals.

Learn more about the RCSI School of Dentistry and the Bachelor of Dental Surgery (BDS) programme.

RCSI is committed to achieving a better and more sustainable future through the UN Sustainable Development Goals.

![]()

![]()